Formation Of 1 Magnesium Upon Cooling Phase Diagram

Pdf Essential Magnesium Alloys Binary Phase Diagrams And Their 12. mg sn (magnesium tin) the mg sn phase diagram has been studied by many researchers. the liquid near the mg rich side of the mg sn system has been investigated by grube , kurnakow and stepanow , hume rothery and raynor using thermal analysis. nayak and oelsen [233, 234] also measured the same using a calorimetric analysis. these results are. Fig. 1 shows the binary magnesium aluminum equilibrium phase diagram. the magnesium rich side of the phase diagram includes equilibrium solid phases α mg and β mg 17 al 12. the phase diagram shows that the equilibrium solid solubility of aluminum at the eutectic temperature is 12.9 wt.% aluminum and decreases to approximately 2 wt.% at room.

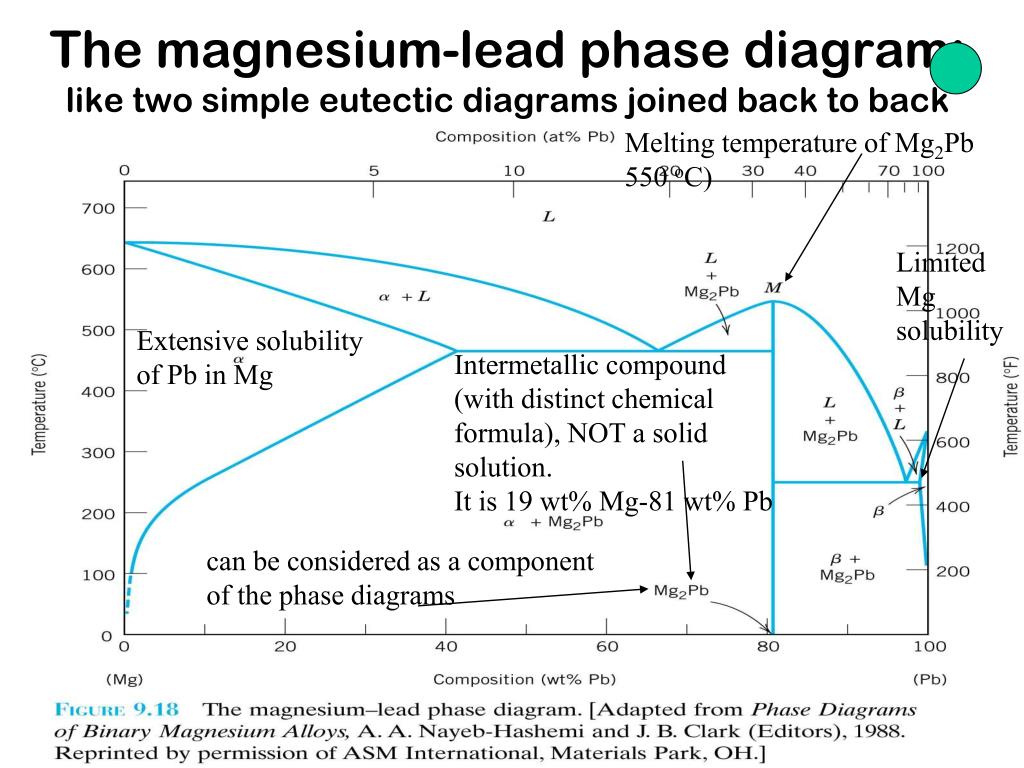

Diagram Lead Magnesium Phase Diagram Mydiagram Online The x ray diffraction (xrd) analysis of mgxb 2 ccb 1.5% ag 4 wt% reveals the formation of the ag mg phase with a high peak intensity at x = 1.075. the other peaks in the spectrum correspond to. 9.34 consider the hypothetical eutectic phase diagram for metals a and b, which is similar to that for the lead tin system, figure 9.8. assume that (1) α and β phases exist at the a and b extremities of the phase diagram, respectively; (2) the eutectic composition is 47 wt% b 53 wt% a; and (3) the composition of the β phase at the eutectic. Wα wl = 1. mass of a component that is present in both phases equal to the mass of the component in one phase mass of the component in the second phase: wαcα wlcl = co. solution of these equations gives us the lever rule. wl = (cα co) (cα cl) wα = (co cl) (cα cl) phase compositions and amounts. Phase diagram is calculated and shown in figure 5. the hte is closely related to the formation of the liquid 2 phase (most likely at the grain boundaries), 9,16 and therefore the hot rolling safe zone is located in the single phase fcc region as shown in figure 5. high temperature embrittlement can be suppressed by avoiding the formation of.

Magnesium Lead Phase Diagram Wα wl = 1. mass of a component that is present in both phases equal to the mass of the component in one phase mass of the component in the second phase: wαcα wlcl = co. solution of these equations gives us the lever rule. wl = (cα co) (cα cl) wα = (co cl) (cα cl) phase compositions and amounts. Phase diagram is calculated and shown in figure 5. the hte is closely related to the formation of the liquid 2 phase (most likely at the grain boundaries), 9,16 and therefore the hot rolling safe zone is located in the single phase fcc region as shown in figure 5. high temperature embrittlement can be suppressed by avoiding the formation of. Some debatable aspects of interpretation of binary phase diagrams playing a key role in the science of alloys are considered. it is shown that the ordering – separation phase transition in binary alloys changes the sign of the chemical interatomic interaction at some temperatures. the mismatch between the mechanism of this process and its representation in the phase diagram is discussed. it. The calphad method, which stands for calculation of phase diagrams, has become a widely used method for effectively calculating phase diagrams of multi component systems in the past a few decades.[1,2,3,4] the essence of this approach is to obtain self consistent thermodynamic descriptions of the lower order systems in terms of known thermodynamic and phase equilibrium data.

Comments are closed.